Everything About Core Drilling Tools: A Comprehensive Guide to Its Types and Uses

Core drilling equipment plays an important duty in discovering subsurface materials across numerous fields. Recognizing the different kinds of core bits and their specific applications is crucial for reliable usage. This tools not only aids in collecting essential geological information however additionally affects decision-making in industries like mining and building and construction. To fully value the importance of core drilling, one need to think about the varied tools readily available and their proper upkeep practices.

Comprehending Core Drilling Tools: An Introduction

Core boring tools plays a crucial role in geotechnical expedition and mineral removal. This customized equipment is created to get round samples of subsurface materials, enabling for comprehensive evaluation of geological developments. The process includes drilling into the ground to remove a core sample, which can give beneficial information regarding dirt structure, rock layers, and natural resource.

Core exploration is essential for website analysis, allowing engineers and geologists to make enlightened decisions pertaining to building and construction tasks and resource extraction. The equipment is normally powered by innovative machinery that guarantees accuracy and efficiency, lessening environmental influence. Different aspects, such as drill bit layout and operational strategies, affect the performance of core boring. Understanding the capacities and restrictions of core drilling equipment is crucial for experts in the field, as it straight affects the top quality and integrity of the collected examples, ultimately guiding calculated preparation and resource management.

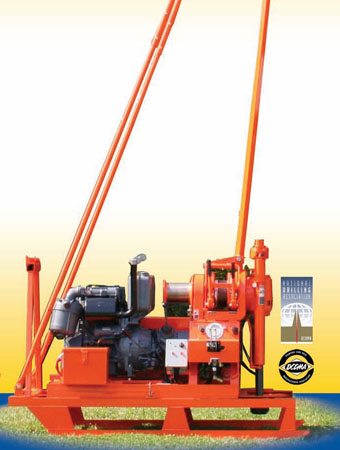

Sorts Of Core Boring Devices and Their Features

Rotary exploration gears offer the essential power to advance the little bit into the ground, while core barrels are utilized to retrieve the core examples. These barrels are available in various styles, such as traditional or wireline, each offering unique benefits in sample recuperation. In addition, casing systems are utilized to support the borehole and prevent collapse. Together, these devices form a cohesive system that permits thorough geological expedition and analysis.

Applications of Core Boring in Numerous Industries

Countless markets depend on core boring for essential applications, varying from mining and environmental researches to building and geotechnical design. Core Drilling Equipment. In mining, core exploration is needed for exploration, permitting companies to assess the mineral material of rock formations and make educated choices regarding source extraction. Ecological research studies make use of core tasting to examine soil and groundwater, assisting to determine contamination and educate remediation initiatives

In construction, core drilling is made use of to Discover More Here produce exact holes in various materials, assisting in the installment of energies and architectural assistances. Geotechnical engineering utilizes core drilling to gather subsurface data, essential for reviewing website problems and guaranteeing the safety and security and stability of frameworks. Furthermore, the oil and gas industry relies upon core boring to remove geological samples, which are vital for tank analysis. Generally, core exploration functions as a fundamental device across these markets, providing valuable understandings and enhancing functional effectiveness.

Variables to Take Into Consideration When Choosing Core Boring Equipment

When selecting core exploration equipment, it is necessary to take into consideration numerous vital variables that can considerably affect the performance and performance of boring operations. The kind of material being pierced is vital, as harder materials might call for specialized little bits and more powerful drill rigs. Next off, the size and depth of the core samples required must determine the option of tools, ensuring that it suits the particular project needs.

In addition, the boring method-- whether rotary or wireline-- can affect performance and expense. The mobility and weight of the equipment are likewise important, especially for tasks in remote locations. Budget constraints ought to be taken into consideration, balancing first costs with long-lasting longevity and maintenance requirements. Lastly, examining producer online reputation and consumer feedback can give understandings right into tools dependability and support solutions. By reviewing these variables, drivers can pick one of the most ideal core boring devices for their tasks.

Upkeep and Best Practices for Core Drilling Devices

Appropriate upkeep and adherence to finest methods are vital for ensuring the longevity and efficiency of core boring tools. Normal assessment is essential; drivers should check for signs of wear, damages, or misalignment before each use. Keeping the devices clean is similarly vital, as particles can prevent performance and bring about premature wear. Oiling moving parts according to the supplier's specs helps in reducing friction and extends tool life.

It is a good idea to adhere to the suggested operating rates and feed rates, as going beyond these limits can trigger getting too hot and tool failure. Operators must additionally determine that the drill bit appropriates for the product being pierced, as using an inappropriate bit can lead to ineffective drilling and raised wear. Proper storage in a dry, safe and secure place stops corrosion and damages, more improving the longevity of core boring devices.

Regularly Asked Questions

What Security Equipment Is Recommended When Utilizing Core Boring Tools?

When using core boring equipment, it is suggested that drivers wear construction hats, safety goggles, handwear covers, ear protection, and steel-toed boots. These things boost individual safety and security and aid protect against injuries throughout boring procedures.

Exactly how Do I Effectively Take Care Of Core Samples?

Core samples ought to be gotten rid of according to local regulations, commonly including securing in suitable containers and transporting to designated waste centers (Core Drilling Equipment). Environmental Discover More Here considerations should be prioritized to protect against contamination and guarantee conformity with security standards

Can Core Boring Be Performed In Extreme Weather Condition Issues?

What Is the Typical Life Expectancy of Core Exploration Tools?

Exist Eco-Friendly Alternatives to Conventional Core Drilling Approaches?

Yes, eco-friendly alternatives to typical core drilling methods exist. Strategies such as geothermal drilling and the usage of eco-friendly lubricating substances reduce environmental effect, advertising lasting methods while keeping effectiveness in core browse around here sampling and removal processes.

Core exploration tools plays a crucial function in checking out subsurface products across numerous sectors. Core exploration devices plays an important function in geotechnical exploration and mineral removal. Rotating boring rigs supply the necessary power to progress the bit into the ground, while core barrels are used to obtain the core samples. When selecting core exploration tools, it is necessary to take right into account a number of key variables that can substantially influence the effectiveness and effectiveness of exploration procedures. When using core exploration tools, it is suggested that drivers put on tough hats, safety and security goggles, handwear covers, ear protection, and steel-toed boots.